Division of Surface Engineering

The Division of Surface Engineering has successfully developed unconventional methods for surface modification of materials, including producing multi-compound and composite surface layers with nanocrystalline structure.

High functional properties of these layers have already gained national and international recognition confirmed by spectacular applications in medicine and industry, including penetrators in Rosetta and InSight missions or implantable artificial heart assist rotary pumps.

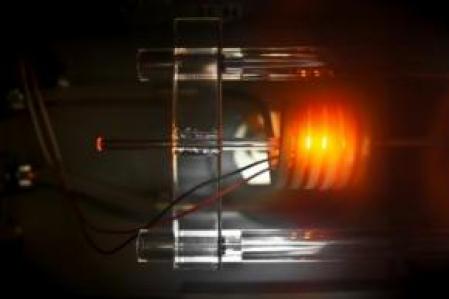

Methods of producing surface layers developed in the Division of Surface Engineering mainly use non-equilibrium plasma and electron, photon and ion beams, new reactive gas atmospheres containing environmentally safe organic compounds – also in so-called hybrid technologies realized by combining various methods of surface treatments like: plasma diffusion treatments (PDT), PVD and CVD processes, chemical and electrochemical deposition and heat treatments. Thus, the produced layers are the latest generation of anti-wear and anti-corrosion layers that enable enhancing mechanical and biological properties of treated structural and functional materials, e.g., steels, titanium and its alloys, nickel alloys, magnesium, aluminum and polymer composites.

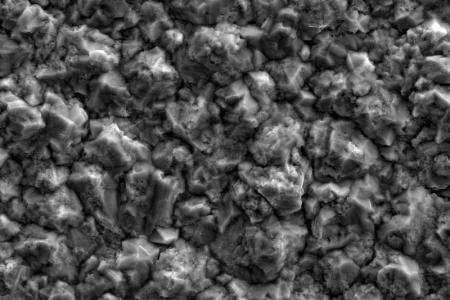

The Division of Surface Engineering also conducts basic research on plasma physics and chemistry, layers formation mechanisms in low temperature plasma, detailed characterization of the produced layers in terms of microstructure, surface topography, chemical and phase composition, residual stress in the produced layers and also mechanical, chemical and biological properties of the layers produced on metallic materials and polymer composites. Research is also being carried out on the production of various steel grades with nanocrystalline structure through the use of heat treatment, as well as their surface treatment in terms of expanding their functional properties and applications.

Professor Tadeusz Wierzchoń, Head of Division of Surface Engineering

Research groups

Electrochemical and chemical treatments

The coatings can be divided in terms of the way they are produced into electrolytic coatings - galvanic (nickel, copper), coatings deposited by chemical reduction (nickel, phosphorus and zinc), chemical conversion coatings (phosphate) and coatings produced by electrochemical anodic oxidation and plasma electrolytic oxidation.

NANOSTAL – technologies of heat and thermochemical treatment

The interest of our group focuses on shaping mechanical and functional properties of steel via selection of chemical composition and heat treatment to obtain optimal phase composition and microstructure.

Surface treatments in low temperature plasma

Our group develops unique methods of surface modification of materials, including multi-component and composite surface layers with a nanocrystalline structure. Excellent functional properties of the produced layers have already gained national and international recognition, confirmed by applications in medicine and industry.