Technology to protect surfaces from icing

The issue is serious. Ice formation and build-up can be a lethal danger in many spheres of life. The risk is still greater if icing occurs on aerodynamic surfaces of aircraft flying at a high speed or on wind turbines, or on key parts of electrical wiring. Rafał Kozera, DSc, Eng. of the Warsaw University of Technology, Faculty of Materials Science and Engineering, has an idea how to solve this problem.

The scientist and his team are working on a project called IceSurfer. The researchers are developing a technology for manufacturing icephobic (i.e. capable of preventing ice formation) surfaces for application in polymer composite components. These specifically include components of aircraft, wind turbine blades and residential power supply devices. The project is funded under the LEADER IX Program by the National Centre for Research and Development.

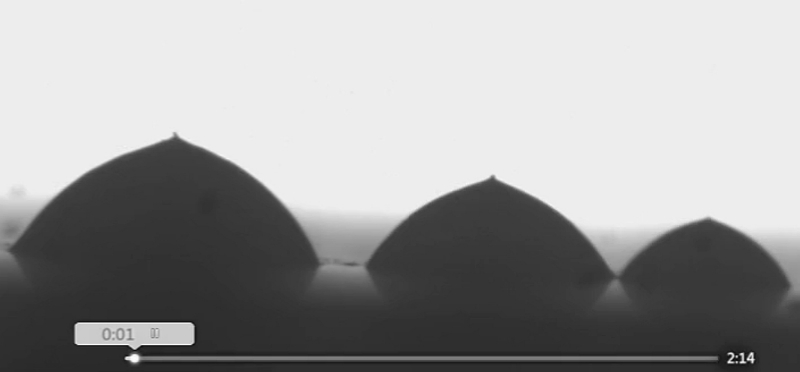

“Composites are coated with a layer of what is known as gelcoat for decoration and protection,” explains Doctor Kozera. “We want to modify that coating so that ice would not adhere, or the ice nucleation process would be delayed as much as possible. And if ice does form, we want it to have a weaker adhesion strength and thus be easier to remove.”

That is why the scientists are producing various additives designed to modify the capabilities of the composite outer layer. To this end, they use nanoparticles and chemical and laser modifications.

The project provides for modifying the gelcoats manufacturing process so that they have the desired properties right from the start. However, the scientists intend their solution to be applied for components already manufactured and in use as well. In such cases, paints that have been modified as appropriate are to be used.

Easier on the environment and on the budget

The technology developed by Doctor Kozera’s team could be an excellent alternative to the current anti-icing and de-icing methods. More often than not, those methods are harmful to the environment, expensive and detrimental to the material durability. Manual ice removal relies on chemicals that have a destructive action on the component structure and, on top of that, get into the air and soil. On the other hand, electrical de-icing solutions consume lots of power, which makes them not only environmentally unfriendly and scarcely efficient but also quite costly, and the cost is high. But the concerns go further than that. De-icing procedures mean that aircraft, turbines or wiring systems are put out of service. And this generates economic losses.

“The literature reports coatings that offer anti-icing protection, but authors tend to be silent about how robust their solutions actually are,” says Doctor Kozera. “One example of that is silicone; it does work but has poor resistance, in particular to erosive factors.”

Hence, its applications in aviation or wind turbines are out of question.

“Those parts that we want to protect are subject to extreme mechanical and thermal stresses and in non-stop service and these are all conditions for high surface degradation,” explains Doctor Kozera. “Coatings are removed from aircraft every 5 to 10 years or even every 3 years at times. The same goes for wind turbines. For this reason, we intend to regenerate components that use our technology. This is where paints will come into play.”

A way for everything

The solution is likely to have a wide range of applications. However, Doctor Kozera makes wind turbines the central focus of his IceSurfer project. “We are now working in laboratories and we are in the stage of preparing samples,” says the scientist. “Eventually, we want to create a demonstrator; small-scale as it certainly will be, it will closely approximate the geometry of a real-world turbine blade. We will also be carrying out air tunnel and real-world testing.”

Checking to prove whether the technology serves its purpose seems to be quite a challenge. How to do the testing and do it right if icing occurs under specific weather conditions and the ice build-up issue does not arise overnight? But there is a way.

“There are methods for accelerating the weather-induced degradation process, so we will manage,” says Doctor Kozera.

Project duration: Jan 1, 2019 to Dec 31, 2021

The project “ICEphobic SURfaces for components based on polymER composites – IceSurfer” is funded under the LEADER IX Program by the National Centre for Research and Development, No. LIDER/16/0068/L-9/17/NCBR/2018