prof. dr hab. inż. Zbigniew Pakieła

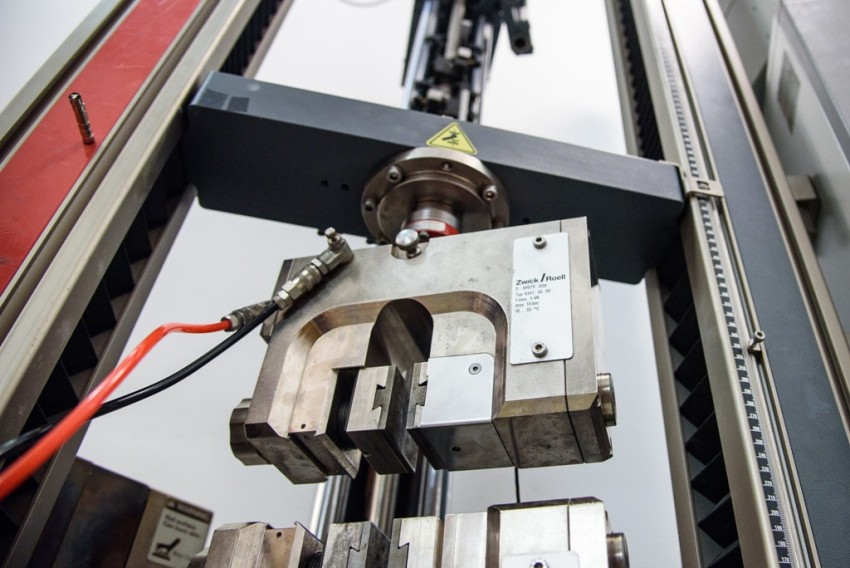

The group’s main activity is related to the topic of mechanical properties testing of materials, both in accordance with standards and non-standardized tests.

A large part of the conducted research concerns the determination of mechanical properties of modern materials available in small volumes using miniaturized samples (tensile tests, minidisks bending tests). The group also specializes in non-contact strain measurements using the digital image correlation method (DIC) on objects of various sizes (from microstructure elements to industrial facilities). In addition to issues related to testing mechanical properties of materials, the group also produces sinters by means of Pulse-Plasma Sintering (PPS) and works on the selection of materials for specific applications. Another area of our group’s activity is damage expertise of devices and construction elements.

Research activities

- Materials mechanical properties testing and development of new research methods (including tensile test of mini-samples, Small Punch Test, measurements of residual stresses)

- Relation between microstructure and properties

- Fracture and fatigue of materials

- Optical methods of deformation measurements

- Application of the inverse method in mechanical properties testing of materials

- Scale effect influence on mechanical properties

- Corrosion protection of magnesium alloys (Warm Spray, Plasma Electrolitic Oxidation, DLC)

- Mg-Sn alloys and their plastic processing

- Ti-Nb alloys for high temperature operation

- TBC coatings

- Selection of materials for service in an aggressive environment (including protective coatings for the mining industry)

- Pulse-plasma sintering (PPS)

- Powder metallurgy (including Fe, Fe-Zr sinters)

- Materials with ultrafine grained microstructure obtained with methods of severe plastic deformation (including ECAP, HPT, hydrostatic extrusion, rolling)

-

Mechanical properties testing of carbon fiber reinforced polymers (CFRP)

Research offer

- Static and dynamic mechanical properties testing, creep tests

- Mechanical properties tests at elevated temperature up to 1300 ° C

- Mechanical properties tests at lowered temperature to -150 ° with smooth regulation, liquid nitrogen, liquid helium

- Displacement / strain measurements using Digital Image Correlation (DIC), laboratory and field tests

- Composites mechanical tests (including ASTM D3410, D6484, D7136 / 7137, D5961)

- Mechanical testing of components (including welds)

- Hardness measurements

-

Failure analysis

Projects

- Development of guidelines for design of innovative technology of shale gas recovery with the use of liquid CO2 on the basis of numerical and experimental research, NCBR, Bluegas II: DIOX4SHELL

- Re-Cover - Layers and coatings with rhenium, its compounds and alloys – properties, areas and methods of applications, NCBR, CuBR/II/4/NCBR/2015

- Development of residual stress measurements method based on 3D Digital Image Correlation, NCN, SONATA 11, 2016/21/D/ST8/02019

- Development of new anti-corrosion coatings for AZ-91E magnesium alloy used for aircraft engine and gear components, NCBR, LIDER V, 097/L-5/2013

- Development of composite materials technology with improved mechanical and electrical properties, NCBR, Innolot 2

-

Fracture characterization of iron and iron-zirconium sinter with nanocrystalline structure, NCN, PRELUDIUM 8, 2014/15/N/ST8/03388

Research collaboration

National collaboration

- Materials Engineers Group Sp. z o.o., Warsaw

- Faculty of Materials Engineering and Metallurgy, Silesian University of Technology, Katowice

- Institute of High Pressure Physics UNIPRESS, Polish Academy of Sciences, Warsaw

- Galactic, Rudna Mała

- Institute of Fundamental Technological Research, Polish Academy of Sciences, Warsaw

- Institute of Power Engineering, Warsaw

International collaboration

- Frantsevich Institute for Problems of Materials Science of NASU, Ukraine

- National Institute for Materials Science (NIMS), Japan

- Hermle Maschinenbau GmbH, Germany

- University of Southampton, Great Britain

- Materiálový a Metalurgický Výzkum s.r.o., Czech Republic

-

Ufa State Aviation Technical University, Russia

Contact

Professor Zbigniew Pakieła

zbigniew.pakiela@pw.edu.pl

+48 22 234 87 24

Division of Materials Design