prof. dr hab. inż. Halina Garbacz

Our team has long-term experience in metallic materials designing and testing, especially titanium and its alloys, which is confirmed by the participation in many R&D projects, also international ones.

The team’s main areas of research include the following aspects:

- designing and characterisation of microstructure and properties of titanium alloys for biomedical applications by way of mechanical, thermo-mechanical processing and surface engineering methods,

- large and severe plastic deformation processes and their ability to obtain nanomaterials and ultrafine-grained materials,

- electrochemical tests of corrosion resistance of metallic materials,

- characterisation of biomedical metals after corrosion and biological tests,

- consolidation of metal chips with the use ofplastic processing,

- characterisation of the microstructure and properties of multilayered laminates produced using the explosive cladding technology,

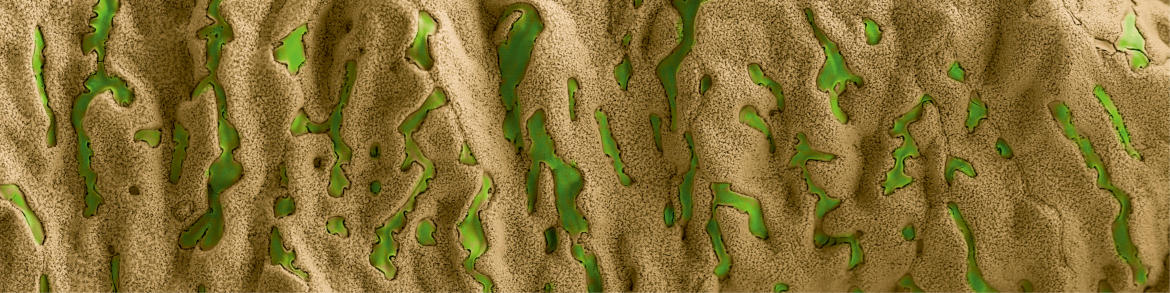

- characterisation of the degradation processes of catalytic gauzes used in the ammonia oxidation process,

- diagnostics of artworks and archaeological objects.

The group cooperates with both Polish and foreign research centres, such as: the Institute for Sustainable Technologies (Radom), the Institute of Physiology and Pathology of Hearing (Kajetany), Institute of Optoelectronics, Military University of

Technology (Warsaw), Friedrich–Alexander University Erlangen–Nürnberg (Germany), Chalmers University of Technology (Sweden), Karlsruhe NanoMicro Facility (Germany), Clemson-MUSC Bioengineering Program (USA).

Services offered

- flat and caliber rolling of metals at a laboratory scaletribological tests in the pin-plate system carried out in a cyclic reciprocating movement

- electrochemical corrosion tests

- characterisation of the degradation processes and quality of metallic surfaces based on microscopic observations and profilometric tests

- preparation of metallic materials, including thin foils for TEM experiments

- microstructural analysis of metals and their alloys (light and electron microscopy)

- heat treatment of metals and their alloys

- surface treatments of metals and their alloys, including mechanical and chemical treatments

- deposition of bioactive coatings on the surface ofmetallic biomaterials

-

sterilisation of biomedical materials

Research infrastructure

- WJ-80s electric rolling mill

- WJSM-60 manual rolling mill

- Autolab PGSTAT302N potentiostat with impedance test module

- Sterilclave 18 COMINO autoclave

- Thermo Scientific™ Midi 40 CO2 incubator with the control of CO2 atmosphere

- UV-VIS AOE spectrophotometer (measuring range of 190-1100 nm)

- Tribotester T-17 for testing material combinations cooperating slidingly in a cyclic reciprocating movement in the pin-plate system

- Zeiss Axio Observer light microscope

- Hitachi SU70 scanning electron microscope

- Hitachi 3500N scanning electron microscope

- TEM JEOL JEM 1200 transmission electron microscope

- Wyko NT9300 optical profilometer

- HYSITRON Triboscope 950 nanoindenter

- Zwick/Roell Z005 tensile strength testing machine

-

Struers TenuPol electrolytic thinning machine

Selected projects

- Development of processing technology for aluminum and composite primary and secondary structures, (Mazowsze/0211/19-00, NCBR, 2020–2021)

- Development of low-waste explosive cladding technology and processing technology of multilayer, high strength, light and super light materials with reactive and functional layers as well as plates cladded explosively with reactive metals and its alloys, (TECHMATSTRATEG, NCBR, 2019–2022)

- Integrated system of tools for the diagnosis and telerehabilitation of sensory organs (hearing, eyesight, speech, balance, smell, taste), (STRATEGMED1, NCBR, 2014–2018)

- Influence of severe plastic deformation on the microstructure of Ti-29Nb-13Ta-4,6Zr alloy for biomedical applications (OPUS 11, NCN, 2016–2021)

-

The influence of low-temperature annealing on the nanostructure evolution and the properties of hexagonal Ti with diversified amount of interstitial elements (OPUS 15, NCN, 2018–2022)

Patents

- Container of a press for plastic forming of metals and their alloys (PAT.417874)

- Method for producing nanocrystalline titanium (PAT.225395)

- Platinum alloy (PtRe) obtained with the use of the melting and casting method or powder mettalurgy, containing platinum, rhenium, and unavoidable carry-over, with the weight content of rhenium in the range of 0.01-40.00% (PAT.228512)

- Platinum alloy (PtRhRe) obtained with the use of the melting and casting method or powder mettalurgy, containing platinum, rhodium (weight content in the range of 0.01-40%), rhenium, and unavoidable carry-over, with the weight content of rhenium in the range of 0.01- 40.00% (PAT.228514)

- Palladium alloy (PdAuRe) obtained with the use of the melting and casting method or powder mettalurgy, containing palladium (weight content in the range of 0.01-30%), gold, rhenium, and unavoidable carry-over, with the weight content of rhenium in the range of 0.01- 40.00% (PAT.228516)

Contact

prof. Halina Garbacz

halina.garbacz@pw.edu.pl

(+48) 22 234 87 92

Division of Materials Design